Albiox focuses on providing high-quality tailored services that meet the standards and special requirements. Albiox has a unique ability to carry out a wide range of projects according to customers’ exact needs.

Use our product customizer tool for tailoring products to your specific cleanroom needs.

Albiox offers comprehensive development and processing services for products, including depyrogenation, packaging, and various sterilization methods such as gamma irradiation, ethylene oxide, and heat sterilization. Additionally, we provide process validation to meet the stringent demands of the pharmaceutical and diagnostic industries.

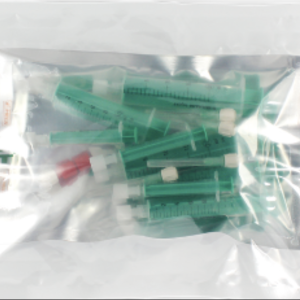

Our ISO Class cleanrooms have substantial capacity for manual and automated packaging and sealing to meet project specifications.

Leveraging extensive expertise and a reliable network of sterilization suppliers, we offer consultation and sterilization management with comprehensive testing data. In-process quality control and regular inspections provide additional assurance and peace of mind.

Cleanroom packaging options include:

– Individual Component Packing

– Single, Double and Triple Bagging Services

– Pouch Sealing

– Poly Bagging

– Labelling

– Liquid Filling

Our services are renowned for quality, compliance, and exceptional customer care. We uphold high standards of quality control and process monitoring. Our dedicated customer service and technical support team responds quickly to inquiries and consult with you at every step to ensure your individual needs are met.

Gamma sterilization technology is very well understood, safe, and easy to validate. It is an effective sterilization method due to its sterility assurance & treatment efficacy, consistently meets product and regulatory requirements, offers proven track record in worker and product safety, flexibility & versatility, effectively sterilizes a wide range of products with different variations in dose requirements, densities, and packaging/box sizes.

Gamma Irradiation is Best Suited For

– Single-use medical products

– Packaged products

– Tissue-based devices

– Implantable medical devices (stents, heart valves, orthopedics)

– Pharmaceutical product and packaging

– Combination medical devices that may contain a pharmaceutical or biologic materials

– Raw materials

EtO Sterilization has broad applications for medical products and medical devices due to its effectiveness at lower temperatures and its general compatibility with a diversity of materials and packaging options. It is particularly effective for sterilizing complex devices, equipment, and packaging with intricate designs or materials that cannot tolerate more aggressive methods. EtO sterilization can permeate through packaging and into intricate crevices, ensuring thorough sterilization while preserving the integrity and functionality of pharmaceuticals, medical devices, and packaging components.

Ethylene Oxide Sterilization is Best Suited For:

– Polymer resin-based products

– Natural materials and metals

– Heat of moisture sensitive products

– Single-use medical devices

– Procedure kits

– Surgical trays

– External terminal sterilization of sealed combination drug devices (filled syringes, drug-coated stents)

Heat sterilization is widely used for medical products and devices due to its ability to effectively eliminate microorganisms through exposure to high temperatures. It is particularly suitable for materials that can withstand high heat, such as glass, metal, and some polymers. Heat sterilization ensures the complete destruction of microorganisms, including spores, without the need for chemical agents, making it a highly reliable method.

Depyrogenation, often achieved through dry heat, is crucial for pharmaceutical applications where endotoxins must be eliminated. This process is essential for materials like glass vials and stainless steel equipment that are used in the production of injectable drugs. By exposing these materials to extreme temperatures, depyrogenation ensures the removal of pyrogens, which are harmful fever-inducing substances, while maintaining the structural integrity of the items.

Heat Sterilization and Depyrogenation are Best Suited For:

– Glassware and ampoules

– Metal surgical instruments

– Stainless steel equipment

– Heat-resistant polymers

– Laboratory equipment

– Injectable drug containers

– Endotoxin removal from pharmaceutical components

Vaporized Hydrogen Peroxide (VHP) sterilization is extensively used for medical devices and pharmaceutical products due to its efficacy at low temperatures and its compatibility with a wide range of materials. VHP is particularly effective for sterilizing complex and sensitive equipment, as it can be applied in a vapor form, allowing it to reach all surfaces, including hard-to-access areas. This method ensures thorough sterilization without leaving toxic residues, making it ideal for delicate items that require a gentle yet effective sterilization process.

Vaporized Hydrogen Peroxide Sterilization is Best Suited For:

– Medical electronics and optics

– Heat and moisture-sensitive materials

– Complex medical devices with intricate designs

– Sterilization of cleanrooms and enclosed spaces

– Surgical instruments and trays

– Medical device packaging

– Reusable and single-use medical devices

With our partners, Albiox offers GMP-quality validation of moist heat steam, dry heat and vaporized hydrogen peroxide sterilizations which include biological indicators and thermocouples. The validation can be done with partial- or full cycle overkill methods. The overkill method describes the process of overkilling reference microorganisms. Typical sterility assurance level (SAL) is 10−6, describing that the expected probability of any surviving microorganism after sterilization is 10−6. The overkill method ensures that the microorganism levels stay within the required range for stringent pharmaceutical customers.

Contamination testing helps to ensure the safety of your products before they are approved for use. The characterization of the purification process for the removal of impurities and testing for possible residues from process steps are also key parts of the chemistry and manufacturing controls (CMC) section of regulatory filings.

Available Contamination Detection Options

– Microbiology Testing

– Mycoplasma Testing

– Sterility Testing

– Pyrogenicity and EndotoxinTesting

– Viral Safety Testing

– Next Generation Sequencing

– Host Cell Protein Assays

– Process- and Product-Related Impurities – HPLC-ELSD, HPLC-CAD, HPLC-MS, ELISA

– Residual DNA Testing

– Additionally, we offer method development and validation for customized, product-specific methods.

Water for Injection (WFI) rinsing is a fundamental process within the pharmaceutical manufacturing space, integral to ensuring the purity and safety of pharmaceutical products.

WFI rinsing serves as a critical step in cleaning and decontaminating pharmaceutical equipment, containers, and surfaces. By rinsing with WFI, manufacturers can effectively remove residues, particulate matter, and microbial contaminants, minimizing the risk of cross-contamination and ensuring product purity.

Specialized equipment and facilities that undergo routine quality control testing, monitoring, and calibration are required to produce this type of water.

Drug or medical device containers/devices such as syringe barrels, plungers, stoppers, seals, vials, bottles, process connectors, often require WFI rinsing prior to their subsequent use downstream of the manufacturing process. Albiox can support the WFI rinse, sterilization, and packaging of your product or device.